Re: P&P question

I do porting, polishing and combustion chamber modifications (and build headers, turbo kits etc etc)...

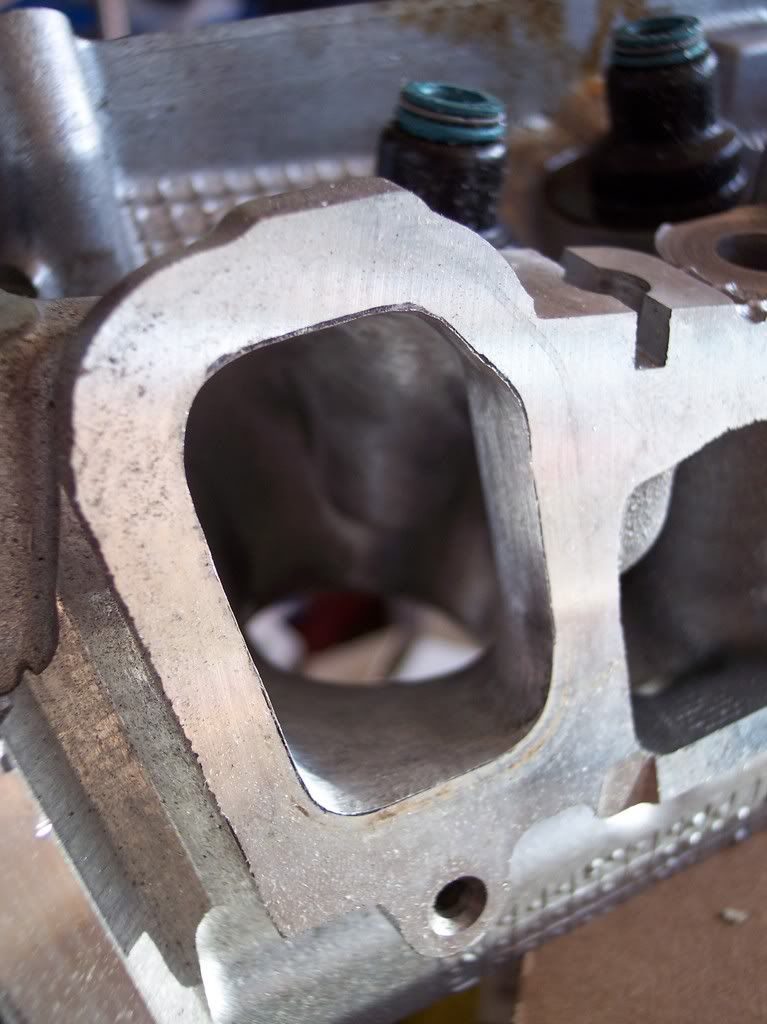

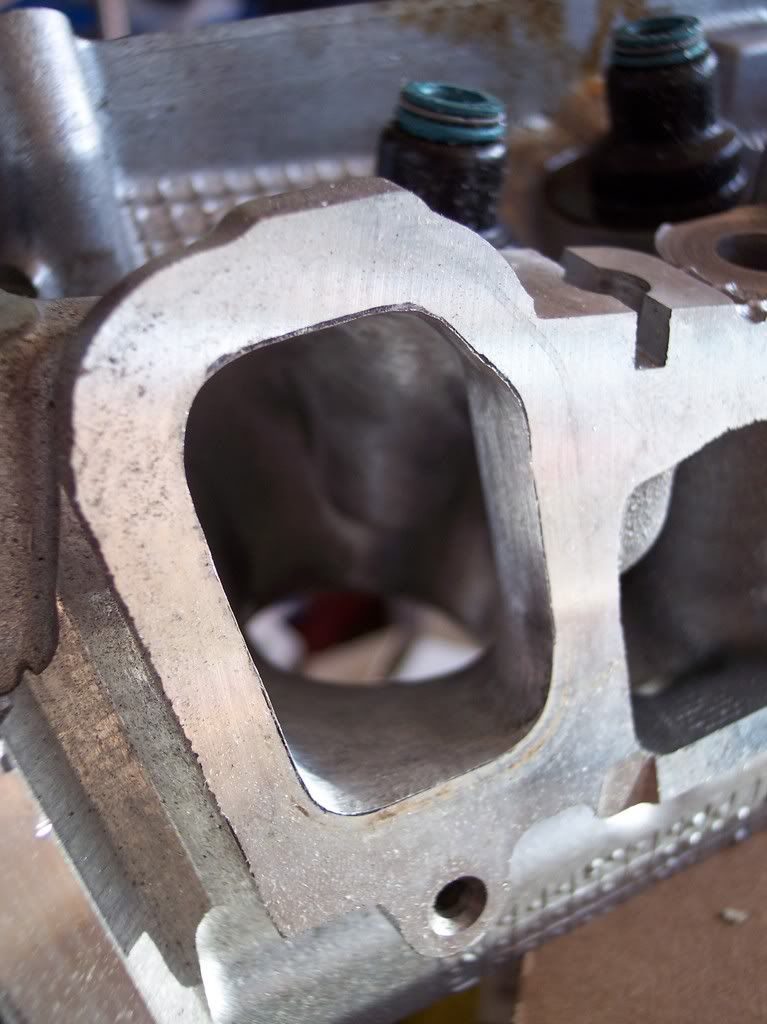

^^^These are some 3500 60* heads.

You can try to port them, but without a flowbench it's like running through the woods with a blindfold on.

I would suggest what some of the others have said and gasket match, then blend the entrance back into the port, and finishing it up by sanding to remove casting marks/seems. Anything before the injectors can be a mirror finish, after don't go any higher then 180-220 grit. Match the intake manifolds to the same gaskets (and mark everything because gaskets can be slightly different from one another). The exhaust ports can also be a mirror finish.

Helps to remove the valves, and try to use some junk ones while grinding to avoid hitting the seats/guides.

Please post results/progress.

I do porting, polishing and combustion chamber modifications (and build headers, turbo kits etc etc)...

^^^These are some 3500 60* heads.

You can try to port them, but without a flowbench it's like running through the woods with a blindfold on.

I would suggest what some of the others have said and gasket match, then blend the entrance back into the port, and finishing it up by sanding to remove casting marks/seems. Anything before the injectors can be a mirror finish, after don't go any higher then 180-220 grit. Match the intake manifolds to the same gaskets (and mark everything because gaskets can be slightly different from one another). The exhaust ports can also be a mirror finish.

Helps to remove the valves, and try to use some junk ones while grinding to avoid hitting the seats/guides.

Please post results/progress.

Comment