Ive had a few people ask how I put an M90 on my car. My thread has very little how to info and more what I did. This thread will hopefully show the ins and outs of putting a M90 in your 4th gen.

First I will say this, your car will be down for a while. Depending on how fast you work this could be as little as 2 months. I worked quite hard on mine and it took a solid 3 months of weekends and weekdays. You will HAVE to pull the motor out the bottom and the motor will have to go in and out at least once. I do not suggest welding the supercharger before you put it in the car. Every car may be different and if you do it my way it will be close to the firewall. It takes a lot of work, fab work, and time. It is fairly affordable. Less than a procharger setup if you do it yourself.

First the car, 3800 4th gen, duh. You will not have to worry about hood clearance, mine is a 97 bird, the lowest of all the hoods and it fits fine. It will not hit the cowl either. Close, but it fits. One issue if you have a drive by wire car you will either need to change the throttle body to a drive by wire one, or change you DBW car to a cable style. I suggest using the stock cable L67 throttle body and converting it to cable opperated style. The firewall will need to be clearanced. The intake near the thermostat will need to be tapped so it will not hit. This only requires about 1/4" of movement. You may also need to tap the firewall back near the SC elbow. Its close.

The motor needs to be a 97+ L67 or L32. 96 and down are OBD1 and are not the series II. I 100% recomend changing the long block to a supercharged motor. Then you dont have to worry about changing heads, and you end up with a more sturdy bottom end. The blocks are the SAME between front and rear wheel drive. All bolt holes are there.

You will be making many runs to the parts store.

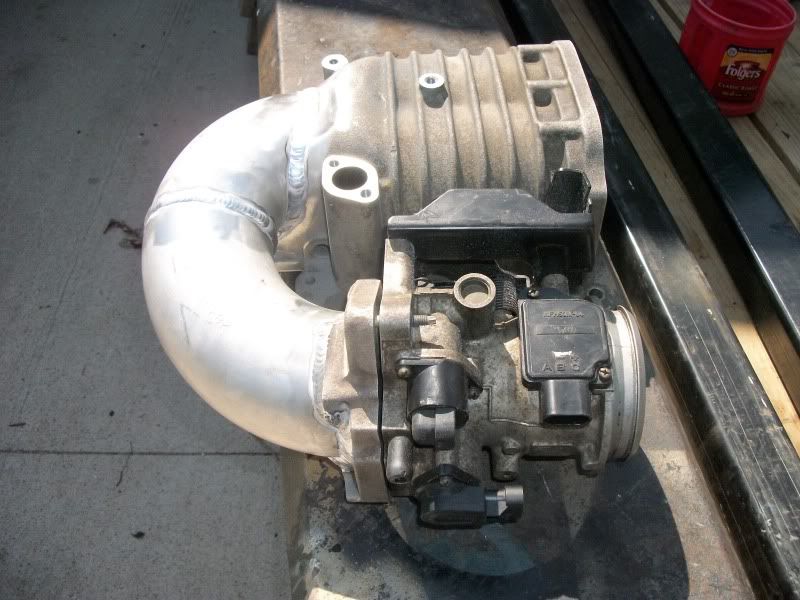

This is the motor I started with. The TB was sawed off, but a complete L67 is a good start.

First I will say this, your car will be down for a while. Depending on how fast you work this could be as little as 2 months. I worked quite hard on mine and it took a solid 3 months of weekends and weekdays. You will HAVE to pull the motor out the bottom and the motor will have to go in and out at least once. I do not suggest welding the supercharger before you put it in the car. Every car may be different and if you do it my way it will be close to the firewall. It takes a lot of work, fab work, and time. It is fairly affordable. Less than a procharger setup if you do it yourself.

First the car, 3800 4th gen, duh. You will not have to worry about hood clearance, mine is a 97 bird, the lowest of all the hoods and it fits fine. It will not hit the cowl either. Close, but it fits. One issue if you have a drive by wire car you will either need to change the throttle body to a drive by wire one, or change you DBW car to a cable style. I suggest using the stock cable L67 throttle body and converting it to cable opperated style. The firewall will need to be clearanced. The intake near the thermostat will need to be tapped so it will not hit. This only requires about 1/4" of movement. You may also need to tap the firewall back near the SC elbow. Its close.

The motor needs to be a 97+ L67 or L32. 96 and down are OBD1 and are not the series II. I 100% recomend changing the long block to a supercharged motor. Then you dont have to worry about changing heads, and you end up with a more sturdy bottom end. The blocks are the SAME between front and rear wheel drive. All bolt holes are there.

You will be making many runs to the parts store.

This is the motor I started with. The TB was sawed off, but a complete L67 is a good start.

Comment